Understanding the Benefits of Automated Guided Vehicles and Autonomous Mobile Robots

In today’s Benefits of AGVs and AMRs rapidly advancing world of industrial automation, the role of Automated Guided Vehicles (AGVs) and Autonomous Mobile Robots (AMRs) has become more significant than ever. Businesses across the globe are under tremendous pressure to enhance efficiency, reduce operational costs, and remain competitive in an increasingly dynamic market. To achieve these goals, more and more organizations are turning toward automated systems that streamline operations and minimize human dependency in repetitive, labor-intensive tasks.

AGVs and AMRs represent the backbone of this automation shift. These intelligent machines have reshaped how industries handle materials, manage workflows, and optimize their resources. Their integration into logistics and manufacturing settings has unlocked faster turnaround times, higher accuracy, and consistent productivity — elements that every modern business needs.

This comprehensive guide explores the far-reaching benefits of AGVs and AMRs, their impact on workflow efficiency, their contribution to cost reduction, and how they integrate with advanced technologies such as AI, machine learning (ML), sensors, mapping systems, and vision technologies. Whether you are in logistics, manufacturing, warehousing, or industrial operations, this guide provides deep insights into how these robotic systems are transforming the industrial landscape.

The Rise of Automation in Modern Industry

Automation has become the driving force behind global industrial transformation. As organizations push toward higher productivity and smarter operations, reliance on AGVs and AMRs has skyrocketed. These robots are engineered to deliver precision, speed, and consistency — qualities that traditional manual labor cannot always promise due to fatigue, human error, and operational limitations.

Industries that once operated using manual forklifts and human carriers are now deploying fleets of intelligent robots that communicate with each other, adapt to real-time environments, and perform critical material-handling tasks without interruption. This marks a new era of robotics-led efficiency.

The Impact of AGVs and AMRs on Workflow Efficiency

Workflow efficiency lies at the core of successful industrial operations. AGVs and AMRs significantly enhance workflow systems by automating material movement, order handling, and transportation tasks.

Precision and Speed in Every Movement

AGVs and AMRs are designed to operate with high precision. Unlike manual labor, which can vary from person to person, these robots maintain consistent accuracy in their routes, handling, and task execution. Their ability to follow fixed or dynamic paths ensures that critical materials reach destinations on time without disruption.

Sophisticated mapping systems and advanced sensors allow AGVs and AMRs to:

- Navigate complex industrial environments

- Avoid obstacles in real time

- Adjust to layout changes

- Maintain consistent operational speed

This combination of precision and intelligent navigation boosts overall workflow efficiency exponentially.

Reducing Human Error with Automated Consistency

Human error is one of the leading causes of delays, damage, and inefficiencies in industrial settings. Fatigue, distraction, and repetitive tasks often contribute to operational flaws. AGVs and AMRs eliminate these challenges by performing repetitive tasks flawlessly, ensuring consistency across processes.

This not only enhances efficiency but also frees up human workers to focus on high-value activities such as decision-making, system monitoring, quality control, and problem-solving.

Smooth Operations and Reduced Downtime

Because AGVs and AMRs work 24/7 without breaks or fatigue, industries experience smoother operations with fewer disruptions. Their continuous availability ensures tasks are completed on schedule, which is especially crucial in industries that rely on tight production cycles.

The result is a streamlined workflow where:

- Processes are completed faster

- Inter-department delays are minimized

- Productivity increases across the entire facility

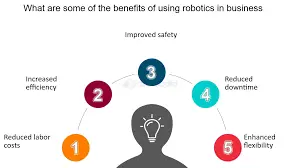

Robotics and Their Role in Reducing Operational Costs

One of the most compelling reasons companies adopt AGVs and AMRs is cost reduction. These systems significantly minimize long-term operational expenses.

Lower Labor Costs and Increased Safety

Manual material handling requires a substantial workforce, leading to higher labor expenses. Additionally, repetitive lifting and carrying can cause workplace injuries. AGVs and AMRs solve this by:

- Reducing dependency on manual labor

- Preventing workplace accidents

- Lowering compensation claims and medical costs

- Ensuring safer work environments

Over time, these savings accumulate, providing an impressive return on investment.

Round-the-Clock Operation for Maximum Productivity

AGVs and AMRs can operate 24/7 without overtime, breaks, or fatigue, significantly increasing total output. Their continuous operation minimizes downtime and ensures a constant flow of materials, which is especially beneficial in manufacturing units with multiple shifts.

Resource Optimization and Reduced Waste

These robots follow optimized routes designed to minimize energy use, reduce wear and tear, and avoid unnecessary travel. This precision leads to:

- Lower energy consumption

- Reduced maintenance costs

- Longer equipment lifespan

- Minimal material damage

Their accuracy also ensures better inventory management, leading to less waste and reduced losses.

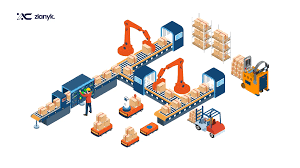

Benefits of AGVs and AMRs in Logistics and Manufacturing

AGVs and AMRs are at the forefront of the logistics and manufacturing revolution, where speed, accuracy, and productivity are paramount.

Automation in Warehouses and Distribution Centers

In logistics, AGVs and AMRs are used to:

- Move goods within warehouses

- Pick, sort, and transport items

- Track inventory levels

- Manage stock placement and retrieval

- Assist in order fulfillment

This automation leads to faster deliveries and improved customer satisfaction.

Enhancing Manufacturing Through Automation

In manufacturing plants, AGVs and AMRs transport raw materials, semi-finished goods, and completed products between various production stages. They ensure that the right materials arrive at the right station at the right time — a critical requirement for continuous production cycles.

Benefits include:

- Higher throughput

- Reduced manual handling

- Improved quality consistency

- Timely production flow

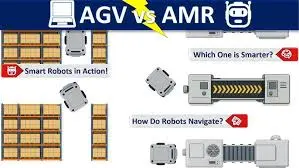

The Power of AI, Machine Learning, Sensors, and Vision Systems

One of the biggest strengths of AGVs and AMRs lies in the technologies they integrate.

Artificial Intelligence and Machine Learning

AI and machine learning empower robots to learn from their movement patterns, adapt to their surroundings, and improve their efficiency over time. They can predict optimal routes, adjust to changes, and enhance navigation performance.

Sensor-Based Navigation and Mapping Systems

AGVs and AMRs rely on advanced sensor systems for navigation, including:

- LiDAR

- Ultrasonic sensors

- Infrared sensors

- SLAM (Simultaneous Localization and Mapping)

These technologies enable them to move safely, avoid collisions, and navigate dynamic environments.

Vision Systems for Intelligent Decision-Making

Vision systems allow these robots to “see” their environment. They help in:

- Identifying objects

- Detecting obstacles

- Reading labels and barcodes

- Enhancing navigation accuracy

This makes AGVs and AMRs more reliable, adaptable, and efficient.

The Future of AGVs and AMRs in Industrial Automation

The adoption of AGVs and AMRs will continue to grow as industries push for smarter, faster, and more automated operations. The combination of robotics, AI, machine learning, and advanced vision systems ensures that these robots will become even more capable in the coming years.

Businesses that invest in automation now will gain a competitive advantage through:

- Higher operational efficiency

- Significant cost reduction

- Enhanced customer satisfaction

- Future-ready infrastructure

AGVs and AMRs are no longer optional additions — they are essential tools for industries striving to remain competitive in 2025 and beyond.

For more

For more exclusive influencer stories, visit influencergonewild