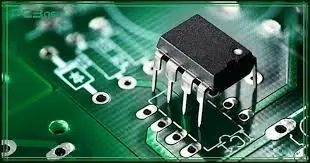

PCBasic: A Leading PCBA Supplier with Transparent Pricing and Fast Prototyping

Choosing the right PCBA supplier in China is one of the most critical decisions for any electronics manufacturer, design engineer, or business looking to scale their production. Among the many suppliers in the market, PCBasic stands out as a trusted, efficient, and highly skilled partner for companies across the globe. With a strong reputation for delivering high-quality PCB fabrication, fast PCB assembly, complete turnkey solutions, and an advanced PCB prototype price calculator, PCBasic helps businesses streamline their development and production processes with unmatched convenience.

This comprehensive guide explains everything you need to know about PCBasic—from its core services and manufacturing capabilities to its end-to-end process, industries served, and the reasons why PCBasic is considered one of the best PCBA suppliers in China.

Why PCBasic Is the Best Choice for PCB and PCBA Services

PCBasic is a professional and experienced Chinese PCB and PCBA supplier offering a complete range of printed circuit board manufacturing and assembly solutions. Known for its fast turnaround, high-quality production, and advanced manufacturing technologies, PCBasic serves startups, large enterprises, research institutions, and global electronics companies.

The company has years of industry experience, enabling it to deliver reliable results for sectors like consumer electronics, automotive, telecommunications, medical devices, robotics, industrial automation, IoT, and more.

PCBasic’s Industry-Level Expertise

PCBasic has earned its reputation through:

- High-precision PCB fabrication

- Advanced SMT and THT assembly capabilities

- Strong engineering expertise

- Strict quality control

- Fast prototype production

- Scalable mass manufacturing

- Professional support from start to finish

Whether the project involves simple single-layer PCBs or complex multi-layer high-frequency boards, PCBasic ensures consistency, reliability, and compliance with global industry standards.

Core Services Provided by PCBasic

PCBasic is known for being a complete one-stop PCB and PCBA manufacturing solution. The company provides everything from PCB fabrication to assembly, testing, and final delivery.

Below is a detailed breakdown of their core services.

PCB Manufacturing

PCBasic excels in high-quality PCB fabrication using advanced machinery and skilled technicians. The company supports a large variety of board types, materials, and technical requirements.

PCB Fabrication Capabilities:

- Single-layer PCBs

- Double-layer PCBs

- Multi-layer PCBs (4, 6, 8, 12, 16+ layers)

- HDI PCBs

- Flexible PCBs

- Rigid-flex PCBs

- High-frequency PCBs (e.g., Rogers, Taconic)

- Heavy copper PCBs

- High-Tg PCBs

- Impedance-controlled PCBs

Fabrication Technologies Used:

- CNC drilling and laser drilling

- Automated optical registration

- Copper plating

- Controlled impedance routing

- Fine-line etching

- Solder mask coating

- Surface finishing (HASL, ENIG, OSP, etc.)

PCBasic ensures that every PCB meets the required specifications and passes strict inspection standards before moving to assembly.

PCBA Assembly (SMT and THT)

PCBasic’s assembly line is equipped with high-speed, high-accuracy machines capable of handling complex and miniaturized components.

SMT (Surface Mount Technology) Assembly

- Component size support down to 01005

- BGA, QFN, and CSP package support

- Solder paste printing

- Reflow soldering

- Pick-and-place with precision robots

- X-ray inspection for BGAs

THT (Through-Hole Technology) Assembly

- Wave soldering

- Selective soldering

- Manual soldering for specialized components

- Leaded and lead-free assembly options

PCBasic’s SMT and THT services ensure reliable solder joints, excellent component placement accuracy, and stable board performance.

Prototype Services

Fast prototyping is one of PCBasic’s biggest strengths. Engineers designing new PCBs often need quick, small-batch prototypes to test performance and functionality. PCBasic supports this with:

- Rapid low-volume PCB manufacturing

- Quick turnaround times

- Accurate cost estimation through the PCB prototype price calculator

- Professional DFM (Design for Manufacturability) support

Whether it’s a basic two-layer test board or a multi-layer product prototype, PCBasic delivers high-quality results quickly.

Testing and Quality Control

PCBasic follows strict quality control processes at every stage of production.

Testing Techniques Include:

- AOI (Automated Optical Inspection)

- X-ray inspection for BGA, QFN, and hidden solder joints

- Flying probe testing

- ICT (In-Circuit Testing)

- Functional testing

- Solder paste inspection systems

These quality checks ensure that every PCB and PCBA assembly meets global reliability standards before delivery.

Full Turnkey Manufacturing Solutions

PCBasic also provides complete turnkey manufacturing services. This means PCBasic manages everything, including:

- PCB fabrication

- Component sourcing

- SMT/THT assembly

- Testing and inspection

- Final packaging

- Global shipping

Turnkey solutions help customers reduce production time, minimize errors, and simplify the entire supply chain.

How the PCB Prototype Price Calculator Works

One of PCBasic’s most powerful features is its PCB prototype price calculator, designed to help engineers, designers, and manufacturers instantly estimate production costs based on essential design requirements.

You Can Enter Parameters Such As:

- Board size (length × width)

- Material type (FR4, Rogers, etc.)

- Number of layers

- Copper thickness

- Surface finish (HASL, ENIG, OSP)

- Quantity

Users can also upload:

- Gerber files

- BOM (Bill of Materials)

This allows the calculator to generate highly accurate, real-time quotations.

Benefits of the Cost Calculator:

- Instant cost estimation

- Transparent pricing

- Faster decision-making

- Better budgeting

- Quick comparison of multiple design options

- Reduced back-and-forth communication

For engineers working on tight deadlines, this tool saves significant time while improving planning accuracy.

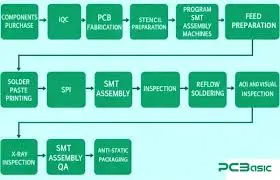

PCBasic’s End-to-End Manufacturing Process

PCBasic follows a highly organized, step-by-step workflow from design upload to final shipping.

Step 1: Upload Gerber Files and BOM

Customers upload their PCB design files (Gerber, drill, pick-and-place) and BOM directly to PCBasic’s platform.

Step 2: Receive an Instant Quote

The PCB prototype price calculator processes the data and instantly provides an accurate quotation.

Step 3: PCB Fabrication Begins

Once approved, PCBasic starts the fabrication process including:

- Material preparation

- Drilling

- Copper plating

- Etching

- Solder mask application

- Surface finishing

- Silkscreen printing

Step 4: Component Assembly

With fabrication complete, the assembly process begins:

- SMT placement

- Reflow soldering

- THT insertion

- Wave soldering

- Final inspection

Step 5: Quality Testing

Every PCB undergoes:

- AOI

- X-ray inspection

- Flying probe testing

- Electrical functionality checks

Step 6: Packaging and Global Shipping

Once inspected and approved, orders are securely packaged and shipped to customers worldwide.

Industries Served by PCBasic

PCBasic supplies PCBs and PCBA services to a wide range of industries.

Consumer Electronics

- Smartphones

- Wearables

- Smart home devices

- Audio systems

- Portable electronics

Automotive Electronics

- ADAS systems

- Vehicle control modules

- Infotainment systems

- ECU (Electronic Control Units)

Medical Devices

- Diagnostic equipment

- Monitoring equipment

- Portable medical devices

Telecommunications

- 5G equipment

- IoT devices

- Network infrastructure systems

Industrial Automation

- Robotics

- Industrial controllers

- Sensors

- Smart factory devices

Why PCBasic Leads the Global PCBA Manufacturing Market

PCBasic’s global leadership is built on consistency, precision, transparency, and customer-first service.

Key Advantages of PCBasic

Speed and Flexibility

- Quick prototyping

- Fast scaling to large production

- Short lead times

International Certifications

PCBasic holds the following certifications:

- ISO 9001

- ISO 13485

- IATF 16949

These ensure global quality standards for different industries.

Advanced Digital Management Systems

PCBasic uses modern systems to track and manage its entire production workflow:

- MES (Manufacturing Execution System)

- ERP

- CRM

- IoT-based tracking

This results in complete traceability, reduced delays, and more efficient manufacturing.

Professional Engineering Support

PCBasic’s engineering team provides:

- DFM checks

- BOM optimization

- Material recommendations

- Cost-saving strategies

Global Customer Network

PCBasic proudly serves customers in over 80 countries, making it a globally trusted PCBA supplier.

Conclusion

PCBasic is more than just a PCB or PCBA supplier—it is a complete electronics manufacturing partner. From PCB fabrication to assembly, testing, component sourcing, and turnkey production, PCBasic offers everything needed to take a project from concept to market.

The company’s innovative PCB prototype price calculator makes budgeting and planning extremely easy, giving customers instant cost insights and helping speed up development cycles. With advanced technology, strict quality assurance, and comprehensive support, PCBasic is the ideal partner for businesses looking for a reliable manufacturing source in China.

Whether you need a simple PCB prototype or full mass production, PCBasic provides world-class quality, fast turnaround, and exceptional customer service.

For more

For more exclusive influencer stories, visit influencergonewild