Workplace injuries cost time, money, and trust in profound ways that ripple through any organization. A few slips, a couple of strains, and suddenly the team’s stretched, morale is down, and productivity takes a hit. These issues happen across all types of workplaces — offices, warehouses, healthcare, and more. The good news is that most of it can be avoided with the right strategies in place.

Too many organisations still treat safety reactively, relying on a report after someone is injured or a policy review following a serious near miss. But this approach often keeps the business stuck in a cycle of preventable harm. It does not have to be this way. A proactive safety programme helps identify risks early, equips staff properly, and builds habits that prevent incidents before they occur.

This expanded guide delves deeper into what health and safety managers, HR teams, and compliance leads can do now — not later — to reduce injuries across the business. Drawing on the latest insights and statistics, we’ll explore practical steps, real-world examples, and the long-term benefits of shifting from reactive to proactive measures. For instance, according to recent data, U.S. companies spent $50.87 billion annually on the top ten causes of serious workplace injuries in 2026. Additionally, employers reported nearly 3.2 million work-related injuries and illnesses in the previous year, highlighting the urgent need for change. By implementing these strategies, organizations can foster environments where people feel safe, valued, and ready to work with confidence.

Laying the Foundation with Consistent Awareness and Learning

People forget safety rules, especially when work is busy. It is not a matter of carelessness — it is about competing priorities and fading memory over time. This is why regular health and safety learning is important. It should not be reserved for high-risk roles alone. Every worker, regardless of their job, faces some level of risk.

The Role of Health and Safety Training in Hazard Recognition

Health and safety training helps people recognise the hazards in their own day-to-day tasks. Repetitive movements, awkward posture, or rushed procedures can all lead to preventable injuries. For example, in warehouses, repetitive lifting without proper technique often results in strains, while in offices, poor ergonomics contributes to long-term issues like back pain. Training programs address these by teaching workers how to identify and mitigate such risks proactively.

To make this effective, organizations should integrate training into onboarding and ongoing professional development. Studies show that proactive safety programs can significantly reduce incident rates by emphasizing early hazard recognition. This not only prevents injuries but also boosts overall employee well-being.

Designing Relatable and Practical Training Sessions

Training needs to be relatable. Keep it short, practical, and flexible. Use examples that match the work environment and avoid jargon. When training is realistic, people are more likely to apply it. Consider incorporating interactive elements like simulations or role-playing scenarios tailored to specific workplaces, such as healthcare settings where rushed procedures during emergencies can lead to slips or strains.

For instance, short modules on ergonomic adjustments can be delivered via mobile apps, allowing staff to learn at their own pace. This flexibility ensures that learning doesn’t compete with busy schedules, reducing fading memory and reinforcing safe habits. Organizations that prioritize such training see improved compliance and fewer preventable harms.

Benefits of Consistent Awareness Programs

Consistent awareness builds a foundation where safety becomes second nature. It equips staff with the knowledge to handle competing priorities without compromising well-being. In high-risk environments like construction or manufacturing, this can mean the difference between a near miss and a serious incident. Moreover, regular refreshers help maintain engagement, ensuring that every worker understands their level of risk and how to manage it effectively.

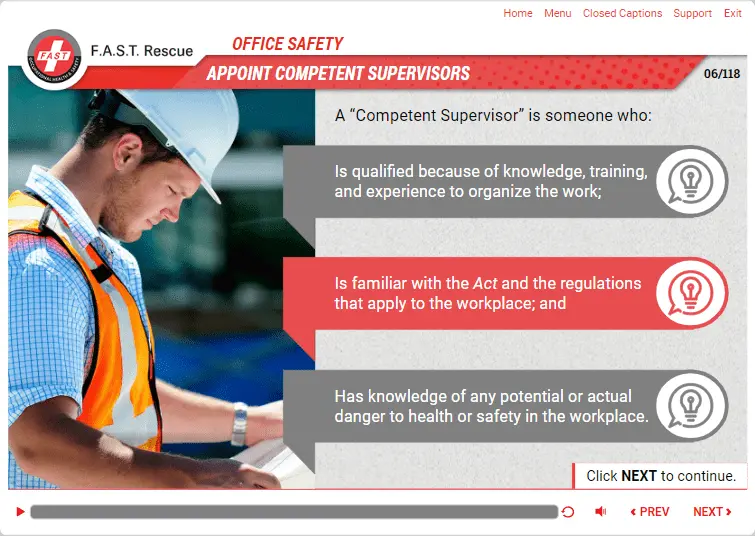

Visual aids can enhance these sessions. Here’s an example of a typical workplace safety training session in an office:

Identifying Common Injury Trends in Your Workplace

No workplace is completely unique, but each has its own injury patterns. You might notice more incidents during shift handovers or when temporary staff are on site. Certain jobs may have a higher frequency of minor injuries that, over time, lead to time off.

Reviewing Incident Reports for Insights

Start by reviewing existing incident reports. Look beyond the major injuries. Pay attention to near misses, equipment faults, or repeated strain complaints. These are early indicators of underlying issues. For example, in healthcare facilities, repeated strain complaints from lifting patients can signal the need for better equipment or training.

Data from 2025 shows that slips, trips, and falls caused over 240,000 nonfatal injuries requiring days away from work in the previous year, with projections rising. By analyzing these patterns, organizations can implement focused changes to break the cycle.

Gathering Staff Insights on Hidden Risks

Speak to staff. They usually know where the risks are — even if those issues have never been formally reported. Their insight is key to spotting trends that might otherwise go unnoticed. Conduct anonymous surveys or informal discussions to uncover these, ensuring that feedback is without blame or judgement.

In warehouses, temporary staff might highlight issues during shift handovers, such as cluttered pathways leading to slips. Understanding these patterns makes it easier to implement focused changes, like new equipment, better layout, or clearer procedures. Small fixes can prevent serious harm and reduce the overall injury rate.

Implementing Data-Driven Improvements

Once trends are identified, act swiftly. This might involve redesigning workflows or investing in safety gear. The benefits include not only fewer injuries but also enhanced productivity, as teams are less stretched by absences. Proactive approaches like this have been shown to reduce costs associated with workers’ compensation and lost time.

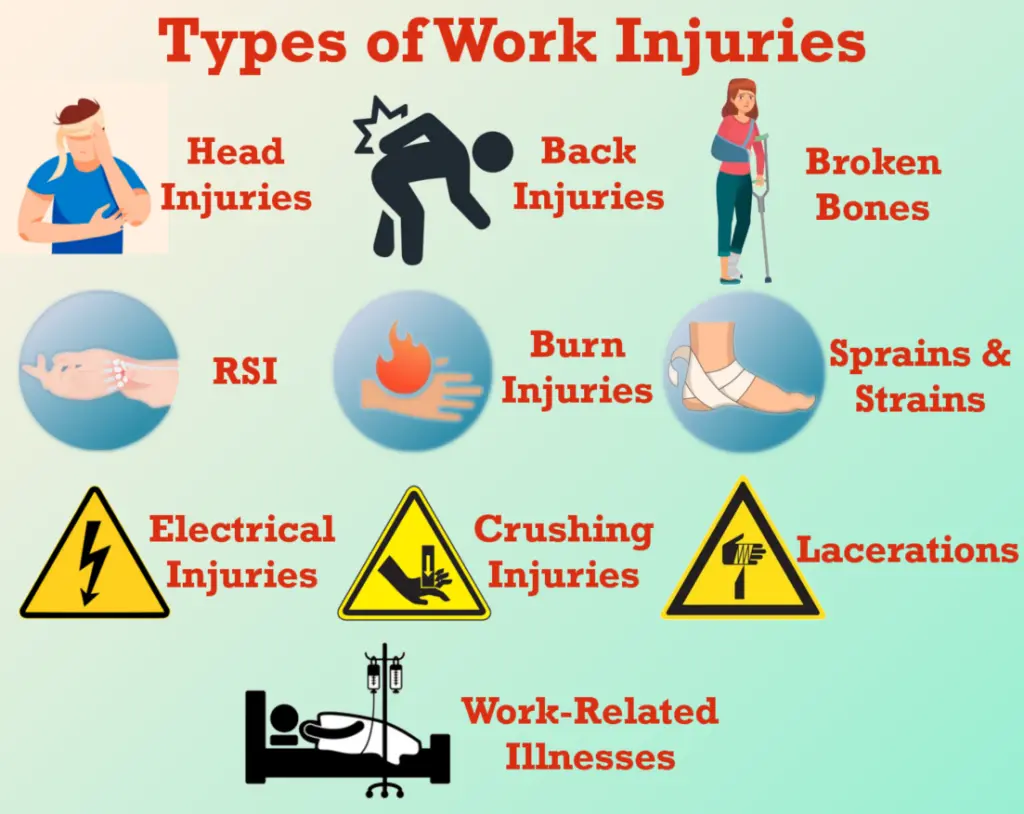

Illustrating common workplace injuries like slips and strains can help visualize the trends:

Involving Staff in Risk Reduction

Safety is everyone’s responsibility, but that only works when staff feel included in the process. If safety is seen as something pushed down from above, people are less likely to engage. But when they are part of identifying risks and designing improvements, ownership grows.

Hosting Interactive Safety Walkthroughs and Workshops

Host short safety walkthroughs or workshops with staff. Let them highlight what feels unsafe. Ask for their ideas to fix it and, where possible, act on them quickly. This involvement fosters a sense of ownership and encourages open feedback channels.

In offices, staff might point out trailing cables or poor workstation set-ups during these sessions. Acting on these ideas not only prevents injuries but also builds trust, as employees see their input leading to real change.

Encouraging Blame-Free Reporting and Feedback

Open feedback channels without blame or judgement. When staff feel safe to speak up, they are more likely to report early warning signs and near misses. This proactive reporting helps prevent actual harm before it escalates.

The people doing the job every day often have the best ideas for making it safer. Involving them transforms safety from a policy into a collaborative effort, enhancing engagement and reducing risks across all roles.

Measuring the Impact of Staff Involvement

Track how involvement affects incident rates. Organizations with high staff engagement in safety see lower turnover and higher morale. This approach ensures that risk reduction is a shared goal, leading to sustainable improvements.

Depictions of staff safety meetings or workshops can inspire similar initiatives:

Reviewing and Improving Reporting Systems

If reporting is awkward, people avoid it. If reporting leads to finger-pointing, they definitely avoid it. This makes the workplace less safe. Reporting systems should be simple and accessible.

Simplifying the Reporting Process

An easy-to-use form, a central contact point, and visible follow-up make all the difference. Staff need to know their concerns will be taken seriously. Digital tools can streamline this, allowing quick submissions via apps or emails.

Encourage reporting of near misses and observations — not just injuries. These are early indicators that help prevent actual harm. In factories or sites, this might include equipment faults spotted before they cause issues.

Using Data to Drive Root Cause Fixes

Once reports are collected, act on them. Do not just produce statistics. Use the data to identify trends and fix root causes. When staff see their input leads to change, trust builds and engagement increases.

This shift from reactive to proactive reporting can lower injury rates significantly, as seen in programs that emphasize quick resolutions.

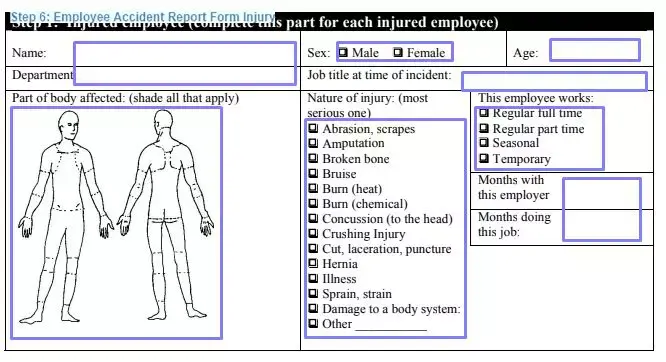

Examples of workplace injury reporting systems or forms:

Fostering a Culture of Continuous Improvement

Regular audits of the reporting system ensure it remains effective. Solicit feedback on its usability and make adjustments, reinforcing that reporting is a tool for prevention, not punishment.

Prioritising Office-Based Risks Alongside High-Risk Tasks

Offices are often overlooked in safety programmes. They are seen as low-risk compared to factories or sites. But risks still exist. Slips on wet floors, poor workstation set-ups, trailing cables, and fire hazards can lead to real injuries.

Addressing Ergonomic and Postural Challenges

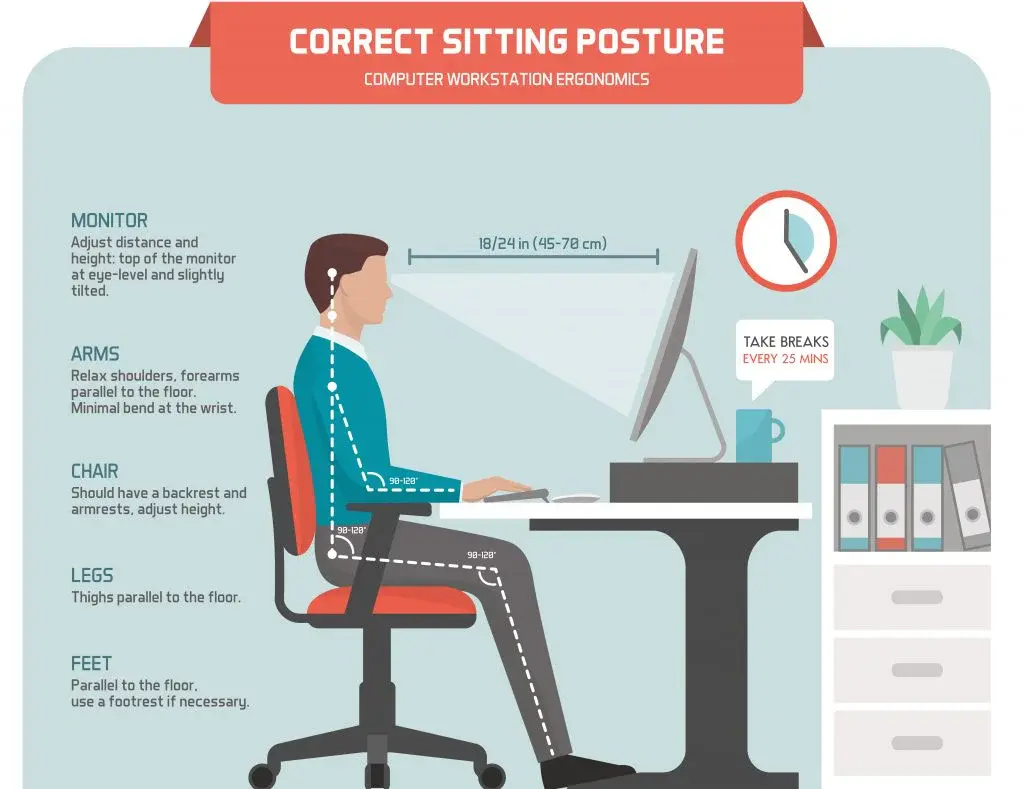

Long hours at a desk without proper support can lead to musculoskeletal issues and eye strain. These problems develop slowly, but they still impact wellbeing and productivity. Running an office health and safety course helps teams understand these risks clearly.

Proper ergonomic setups, such as adjustable chairs and monitors, can mitigate these. In 2025, musculoskeletal disorders remain a top cause of workplace absences, underscoring the need for attention.

Integrating Office Safety into Broader Strategies

It also supports compliance with workplace standards. Including offices in the safety strategy shows that safety matters everywhere — not just on the shop floor. This holistic approach prevents the oversight of subtle risks like eye strain from prolonged screen time.

Practical Steps for Office Risk Mitigation

Conduct ergonomic assessments and provide training on posture. Simple changes, like cable management, can prevent slips and falls. These efforts ensure that office workers are as protected as those in high-risk tasks.

Visual guides for ergonomic workstation setups to prevent musculoskeletal issues:

Tracking Performance and Adjusting the Safety Programme

A proactive safety programme is not something you set and forget. Set clear performance indicators. Track how many incidents are reported, how quickly they are resolved, and how many teams complete safety checks or take part in training.

Establishing Key Performance Indicators

Use this information to review effectiveness. If some areas show fewer reports, it could be a sign of underreporting rather than improved safety. Metrics should include both quantitative data, like incident rates, and qualitative feedback.

In warehouses, where injury rates are higher at 5.5 cases per 100 employees, tracking helps pinpoint areas needing adjustment.

Gathering Qualitative Feedback for Holistic Review

Go beyond numbers. Speak to people. Ask how safe they feel, whether they understand the risks, and whether they know how to report concerns. This feedback ensures the programme adapts to evolving needs.

Programmes that adapt stay relevant. Programmes that stagnate often lose impact, leading to increased preventable harms.

Iterative Adjustments for Long-Term Success

Regular reviews allow for timely tweaks, such as updating training based on new trends. This dynamic approach maintains momentum and sustains reductions in injuries.

Making Safety Part of the Culture, Not Just the Policy

Policies are important, but they only go so far. Culture is what people follow when no one is watching. If safety is only discussed during audits or after incidents, it stays on the margins.

Embedding Safety in Daily Operations

But if it is part of daily work — mentioned in meetings, discussed during handovers, praised when done well — it becomes the norm. Leadership plays a key role. When managers model safe behaviour and respond to concerns quickly, they set the standard for others.

Celebrate small wins. Recognise staff who report issues, suggest improvements, or support safer ways of working. These actions build a culture where safety is valued.

The Role of Leadership in Cultural Shift

Leaders should integrate safety into every aspect, from team meetings to performance reviews. This fosters a proactive mindset, reducing reliance on reactive measures.

Proactive cultures not only prevent injuries but also enhance operational efficiency and employee retention.

Sustaining Engagement Through Recognition

Regular recognition events or shout-outs can reinforce positive behaviors, making safety a core value rather than an obligation.

Infographics or posters promoting safety culture in the workplace:

Wrapping Up: The Path to a Safer Workplace

Reducing workplace injuries is not about having the most detailed policy. It is about building habits that protect people every day. A proactive safety programme helps organisations get ahead of the risks. It identifies patterns, engages teams, and focuses on practical action. Training and reporting become tools, not obligations.

When health and safety is part of how things are done — in every task, every role — injuries fall, morale rises, and the whole workplace becomes stronger. By leading from the front, HR teams and safety managers can create environments where people feel safe, valued, and ready to work with confidence. The shift to proactive measures not only avoids the costs of injuries — estimated at billions annually — but also cultivates a resilient, productive workforce. Embracing these strategies ensures long-term success in preventing harm and fostering trust.

For more

For more exclusive influencer stories, visit influencergonewild