In today’s manufacturing environment, speed has become one of the most critical drivers of value creation. Rising input costs, supply chain instability, and tightening margins leave little room for slow decisions or delayed execution. Manufacturers that move too slowly often see performance erode before improvements ever reach the bottom line. Operations consulting exists to break this pattern by helping organizations act decisively and convert operational complexity into measurable results.

Unlike strategy work that remains conceptual, operations consulting is grounded in execution. Its purpose is to improve how products are manufactured, how materials move, how people perform, and how capital is deployed across the organization. When done well, it delivers faster and more sustainable gains in cost reduction, throughput, service levels, and cash flow. In a competitive manufacturing landscape, execution speed is no longer optional—it is a requirement.

Speed as the Primary Lever for Value Creation

In manufacturing, value is rarely lost due to a lack of ideas. More often, it disappears because decision-making is slow and execution is fragmented. Projects stall between departments, ownership becomes unclear, and improvement initiatives take months before any visible impact appears. Operations consulting changes this dynamic by treating speed as a core design principle rather than a byproduct.

By rapidly diagnosing operational bottlenecks and focusing leadership attention on the highest-impact constraints, consultants help organizations move from analysis to action. Whether the issue is low equipment availability, excessive lead times, or bloated inventory, the emphasis is on fast, focused interventions that deliver early results. These quick wins build momentum, and that momentum becomes the foundation for long-term cultural change.

Why Faster Execution Changes Culture

Speed does more than improve metrics; it reshapes behavior. When teams see that decisions lead to immediate action and visible outcomes, engagement increases. People stop waiting for perfect information and start acting on what matters most. Over time, this creates a culture where accountability and continuous improvement become the norm rather than exceptions.

Aligning Operations with Financial Outcomes

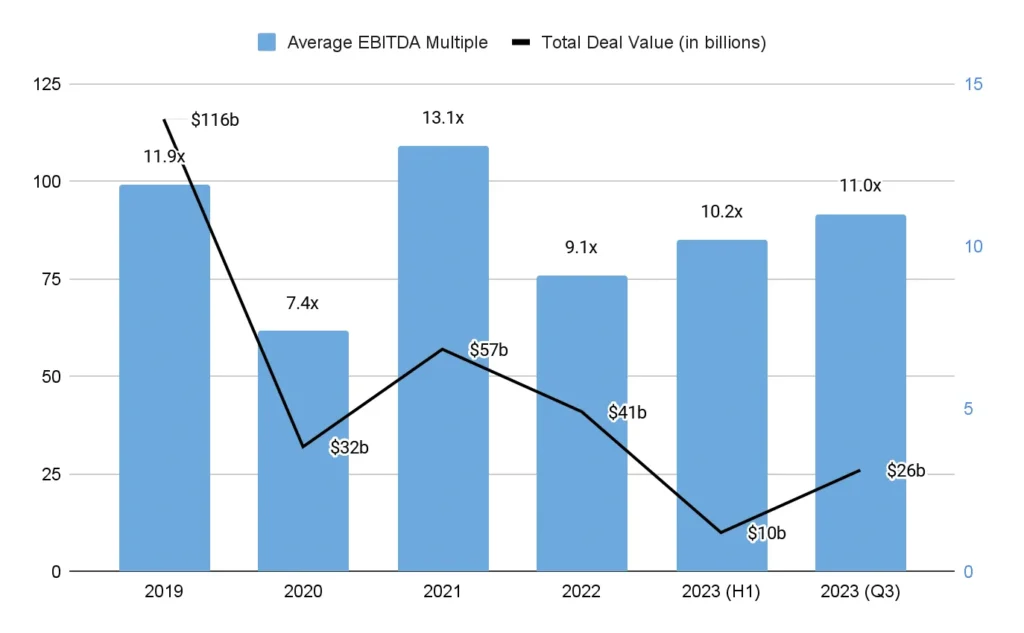

One of the most persistent challenges in manufacturing is the disconnect between operational improvement and financial performance. Teams may successfully improve processes on the shop floor, yet leadership struggles to see a clear impact on EBITDA, margins, or cash flow. Operations consulting bridges this gap by directly linking operational metrics to financial outcomes.

Approaches such as those used by TBM Consulting apply a value-creation lens to every initiative. Productivity improvements translate into measurable labor cost reductions. Shorter cycle times free up working capital. Better planning reduces premium freight, excess inventory, and expediting costs. When operational teams understand how their actions affect financial results, execution becomes sharper and decision-making improves.

Making Financial Impact Visible

Visibility is critical. Operations consulting helps manufacturers establish clear cause-and-effect relationships between actions and outcomes. When financial impact is transparent, leaders can prioritize initiatives more effectively, and teams gain confidence that their efforts matter. This clarity reinforces discipline and accelerates results across the organization.

Manufacturing Excellence Beyond the Factory Floor

While production efficiency remains central, modern operations consulting extends far beyond the factory floor. True value creation requires optimizing the entire operating model, from procurement and planning to logistics and workforce deployment. Manufacturing performance is only as strong as the weakest link in the value chain.

Supply chain resilience has become a strategic priority, especially in an era of geopolitical uncertainty and volatile demand. Operations consultants help manufacturers redesign supply networks, improve planning accuracy, and diversify sourcing strategies. The goal is to reduce risk without sacrificing responsiveness or cost competitiveness.

Organizational Design and Human Capital

Human capital is often the hidden constraint in manufacturing performance. Skills gaps, unclear roles, and outdated incentive structures slow execution even when processes are well designed. Leading operations consulting engagements integrate workforce strategy with operational improvement. This ensures that people, processes, and performance metrics are aligned around value creation.

By clarifying decision rights and simplifying organizational structures, manufacturers can reduce friction and move faster. When talent is deployed where it creates the most value, execution accelerates and results become sustainable.

Value Creation for Private Equity and Growth-Focused Manufacturers

For private equity-backed manufacturers, speed is especially critical. Investment horizons are shorter, and value creation plans must deliver results quickly to support the deal thesis. Operations consulting plays a central role during ownership transitions, carve-outs, and post-acquisition integrations by translating strategic intent into rapid execution.

Through accelerated diagnostics and structured execution roadmaps, consultants help portfolio companies identify value early and capture it before complexity slows progress. The focus is not just on identifying opportunities, but on implementing them at pace. Early wins create confidence with investors and management teams alike.

Supporting Growth Without Losing Control

Growth-focused manufacturers face a similar challenge. As volumes increase and complexity grows, execution often lags behind ambition. Operations consulting helps these organizations scale without losing control by reinforcing discipline, standardizing core processes, and building internal capability alongside performance improvements.

Data-Driven, Execution-Focused Transformation

Modern operations consulting is increasingly data-driven, but data alone does not create value. The real differentiator lies in how insights are translated into action. Successful engagements combine analytical rigor with hands-on execution, ensuring that recommendations are practical, realistic, and implemented quickly.

Consultants work side by side with internal teams, not just as advisors but as partners in execution. This approach accelerates results while building internal capability. Over time, manufacturers develop the confidence and discipline needed to sustain continuous improvement independently.

Building Capability, Not Dependency

The goal is not short-term fixes. Operations consulting focuses on embedding skills, tools, and behaviors that allow organizations to improve continuously. When teams understand both the data and the actions required, performance gains last long after the engagement ends.

Sustaining Faster Value Creation in Manufacturing

Faster value creation is not a one-time initiative. It requires a fundamental shift in mindset. Manufacturers that consistently outperform their peers embed speed, accountability, and value focus into their operating culture. Operations consulting acts as a catalyst for this shift by simplifying complexity and reinforcing execution discipline.

In an environment where delays are costly and uncertainty is constant, manufacturers need partners who understand both operations and outcomes. By aligning strategy with execution and speed with value, operations consulting enables organizations to move decisively and compete effectively.

Conclusion: Turning Execution Speed into a Competitive Advantage

In manufacturing, the ability to act quickly and execute effectively determines whether value is captured or lost. Operations consulting provides the structure, focus, and momentum needed to translate operational challenges into measurable financial results. By aligning execution with financial outcomes, strengthening supply chains, and unlocking the full potential of human capital, manufacturers can achieve faster and more sustainable value creation.

With a speed-driven, execution-focused approach such as that delivered by TBM consulting, organizations are better equipped to navigate uncertainty, outperform competitors, and build lasting operational excellence in an increasingly demanding global market.

FAQS

What is operations consulting in manufacturing?

Operations consulting helps manufacturers improve execution across production, supply chain, workforce, and capital deployment to achieve better cost, speed, and performance results.

How does operations consulting create value?

It focuses on faster execution, removing bottlenecks, and linking operational improvements directly to financial outcomes like EBITDA, cash flow, and working capital.

Is operations consulting only about the factory floor?

No, modern operations consulting covers the entire operating model, including procurement, planning, logistics, organization design, and human capital.

Why is speed so important in manufacturing operations?

Slow decision-making and execution increase costs and reduce competitiveness. Faster execution helps manufacturers capture value before market conditions change.

How does operations consulting support financial performance?

Operational improvements such as productivity gains, shorter cycle times, and better planning directly translate into cost savings and improved cash flow.

Can operations consulting help private equity–backed manufacturers?

Yes, it plays a key role in rapid value creation during ownership transitions, post-acquisition integration, and compressed investment timelines.

What makes execution-focused consulting different?

Execution-focused consulting emphasizes hands-on implementation, not just recommendations, ensuring changes are applied quickly and sustainably.

How does data factor into operations consulting?

Data is used to identify constraints and measure impact, but value is created when insights are translated into real operational actions.

Does operations consulting build internal capability?

Yes, effective engagements work alongside internal teams to build skills and discipline, reducing long-term dependency on consultants.

Why do manufacturers choose firms like TBM Consulting?

They focus on speed, execution, and measurable value creation, aligning operational improvements directly with financial results.

For more

For more exclusive influencer stories, visit influencergonewild