Integrating Cooling Fans into Industrial Cabinets: Best Practices for 2025

Cooling Fans in Industrial Cabinets In modern industrial environments, industrial cabinets house sensitive electronic components, controllers, and automation devices that are crucial for operational efficiency. While these cabinets are designed to protect equipment from dust, moisture, and mechanical impact, they can also trap heat. Over time, accumulated heat can lead to equipment malfunction, reduced lifespan, or expensive downtime. Properly integrating cooling fans into industrial cabinets is therefore essential for maintaining equipment performance, safety, and long-term reliability.

This comprehensive guide offers actionable insights on assessing cooling needs, selecting the right fans, optimizing placement, implementing automation, customizing solutions, and maintaining equipment to ensure industrial cabinets operate efficiently and effectively.

Why Cooling Matters in Industrial Cabinets

Industrial cabinets are often compact enclosures with high-density electronic equipment. These components generate substantial heat during operation, and without effective cooling, this heat can accumulate, forming hot spots. Hot spots not only compromise performance but can also accelerate the aging of components, increasing the risk of failure and operational interruptions.

Excessive heat can lead to several critical issues, including:

- Reduced Equipment Lifespan: Thermal stress accelerates wear on electronic circuits and power components.

- Operational Inefficiency: Overheated devices may throttle performance to compensate, reducing overall productivity.

- Safety Risks: High temperatures can degrade insulation, increase fire hazards, and affect surrounding equipment.

- Increased Energy Consumption: Devices consume more energy when operating under elevated temperatures, impacting overall efficiency.

Even a slight reduction in temperature can significantly improve reliability, extend the service life of components, and lower maintenance costs. Efficient cooling ensures continuous operation, enhances energy efficiency, and preserves critical equipment in demanding industrial environments.

Assessing Cooling Requirements

Before selecting fans, it is crucial to accurately assess the thermal characteristics and cooling requirements of the cabinet. Start by calculating the total heat load the combined heat generated by all internal components, including PLCs, drives, transformers, power supplies, and other electronic devices. Manufacturers typically provide heat dissipation specifications for each device, which can guide the calculation of the required airflow in cubic feet per minute (CFM) or liters per second (L/s).

Environmental factors play a significant role in determining cooling requirements. Ambient temperature, humidity, dust levels, and proximity to heat sources influence fan capacity and type. Cabinets installed near industrial ovens, motors, or areas with poor ventilation require more robust cooling solutions.

Space constraints may necessitate specialized solutions such as DC centrifugal fans, which provide high pressure in small form factors. It is often advisable to slightly overestimate cooling needs to provide a safety margin, ensuring equipment remains within optimal temperature ranges even during peak operation.

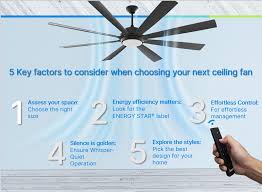

Selecting the Right Fan Type

Selecting an appropriate fan type is critical for ensuring optimal airflow and heat dissipation. Each type of fan has distinct characteristics suited for specific applications:

- Axial Fans: Ideal for low-pressure, short-distance airflow applications, axial fans are cost-effective and suitable for less dense cabinets. They move air directly along the axis of the fan, providing uniform ventilation.

- Centrifugal Fans: These fans generate higher static pressure, making them ideal for densely packed enclosures or ducted systems where airflow must navigate obstacles. They are highly effective at maintaining consistent cooling across complex cabinet layouts.

- Mixed-Flow Fans: Combining axial and centrifugal principles, mixed-flow fans offer balanced airflow with moderate pressure. They are typically quieter and more energy-efficient, making them suitable for noise-sensitive environments.

- Specialized Fans: Depending on environmental challenges, IP-rated fans provide dust and moisture resistance, low-noise fans reduce operational disturbances, and high-temperature fans ensure reliable operation under extreme conditions.

The selection process should consider airflow requirements, pressure ratings, noise constraints, and durability against environmental factors. Collaborating with experienced fan manufacturers ensures that selected fans meet the operational demands of the cabinet while remaining energy-efficient and long-lasting.

Optimizing Fan Placement for Efficient Cooling

Proper fan placement is essential to achieve uniform airflow and prevent hotspots within the cabinet. Key strategies include:

- Inlet and Outlet Positioning: Place inlet fans at the cabinet base to draw in cool air, while outlet fans are positioned at the top to expel warm air. This arrangement facilitates natural convection and promotes efficient circulation.

- Avoiding Air Recirculation: Hot and cold air streams should not cross, as recirculation can reduce cooling efficiency. Implementing baffles or ducting helps direct airflow to high-heat areas.

- Targeted Airflow: Direct airflow to critical components such as power supplies or controllers. This focused cooling reduces localized overheating and improves overall system reliability.

For high-density cabinets, advanced tools like Computational Fluid Dynamics (CFD) simulations can optimize fan placement. CFD models visualize airflow patterns, identify hotspots, and guide ducting placement to enhance cooling performance.

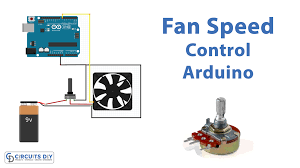

Fan Speed Control and Automation

Modern industrial cooling systems increasingly rely on automation to maximize efficiency and performance. Variable-speed fans adjust their operation according to temperature, ensuring adequate cooling without unnecessary energy consumption.

Smart controllers equipped with temperature and humidity sensors can regulate fan speed in real time, enabling automated responses to fluctuating operational conditions. Integration with PLCs or Industrial IoT platforms allows centralized monitoring, predictive maintenance, and real-time alerts if temperatures exceed predefined thresholds.

Automation offers several benefits:

- Energy Savings: Fans operate only when necessary, reducing electricity costs.

- Extended Fan Lifespan: Reduced operating hours minimize mechanical wear.

- Consistent Performance: Automated systems maintain optimal temperatures even under variable loads.

Industrial facilities adopting automated fan control can achieve significant efficiency improvements while reducing manual intervention.

Customizing Cooling Solutions

Standard fan configurations may not always meet the demands of specialized industrial applications. Customized solutions can optimize performance according to cabinet layout, operational requirements, and environmental challenges.

Customizations may include:

- Adjusting fan size, RPM, and airflow direction to match specific component arrangements.

- Designing low-noise blade profiles for laboratories or control rooms.

- Using high-efficiency blade designs to maximize airflow without increasing energy consumption.

- Selecting corrosion-resistant or high-temperature materials for harsh environments.

Partnering with custom fan manufacturers ensures that cooling solutions are tailored to meet operational, environmental, and spatial requirements, providing maximum efficiency and reliability.

Maintenance and Operational Longevity

Regular maintenance is essential to sustain cooling performance:

- Cleaning Dust and Debris: Accumulated dust reduces airflow and increases operating temperatures.

- Alignment and Vibration Checks: Misaligned fans may vibrate, producing noise and premature wear.

- Filter Replacement: Maintaining clean filters ensures efficient airflow.

- Monitoring Temperature Trends: Detects anomalies early and prevents equipment overheating.

Consistent maintenance ensures optimal cooling, reduces downtime, and extends the operational life of both fans and cabinet components.

Practical Applications and Case Studies

Automotive Manufacturing Cabinet: PLCs in a compact cabinet were overheating during peak production. High-pressure centrifugal fans with variable-speed control were installed, reducing temperatures by 15°C and improving uptime by 20%.

Food Processing Plant: High humidity affected electronic drives. IP55-rated axial fans with ducted airflow maintained stable temperatures, reducing equipment failure and cutting maintenance costs by 30%.

Electronics Testing Lab: Noise-sensitive equipment required cooling without disruption. Low-noise mixed-flow fans with smart controllers maintained safe operating temperatures while minimizing noise in the laboratory.

These examples illustrate the impact of thoughtful fan selection, strategic placement, and automation in maintaining operational efficiency across diverse industrial environments.

Long-Term Benefits of Effective Cooling

Integrating cooling fans into industrial cabinets offers multiple long-term benefits:

- Enhanced Reliability: Components remain within safe operating ranges.

- Extended Equipment Lifespan: Reduced thermal stress prolongs operational life.

- Energy Efficiency: Optimized fan control lowers electricity consumption.

- Operational Continuity: Reduced downtime due to overheating.

- Scalability: Cooling solutions can adapt as industrial needs evolve.

Effective thermal management ensures that industrial facilities can maintain productivity, protect equipment, and remain competitive in demanding operational settings.

Conclusion

Cooling is a fundamental requirement in industrial cabinet design, not an optional consideration. By accurately assessing heat loads, selecting the appropriate fans, optimizing placement, implementing automation, customizing solutions, and performing regular maintenance, industrial facilities can achieve significant improvements in equipment performance, operational efficiency, and reliability.

Properly integrated cooling fans ensure smooth operation, protection of sensitive equipment, and a competitive edge in increasingly demanding industrial environments. In 2025 and beyond, effective thermal management remains essential for sustainable and efficient industrial operations.

For more

For more exclusive influencer stories, visit influencergonewild