Industrial control cabinet cooling plays a critical role in protecting sensitive electrical and electronic components used in production, automation, and process control. As equipment density increases and operating environments become harsher, effective cooling is no longer optional—it is a core reliability requirement. For broader industrial insights and performance-driven strategies related to modern systems, explore expert resources available on Influencer Gone Wild.

Smart cooling strategies protect components from thermal stress, stabilise performance, and reduce costly downtime. This guide explains how to design efficient, scalable, and compliant cooling solutions for industrial control cabinets, helping businesses improve reliability, extend equipment lifespan, and support uninterrupted operations.

Why Thermal Management Is Critical in Industrial Cabinets

Heat is one of the most common causes of electrical component failure. Excessive temperatures accelerate component ageing, increase failure rates, and reduce system reliability. Many competitors focus only on cooling hardware, but the real issue is thermal management strategy—understanding why heat builds up and how it impacts long-term operation.

Poor thermal control leads to unpredictable shutdowns, false alarms, and reduced accuracy in control systems. Effective cooling ensures stable operating temperatures, protects investment in equipment, and supports continuous production without unplanned interruptions.

Understanding Heat Sources Inside Control Cabinets

Heat Generated by Power Supplies and Drives

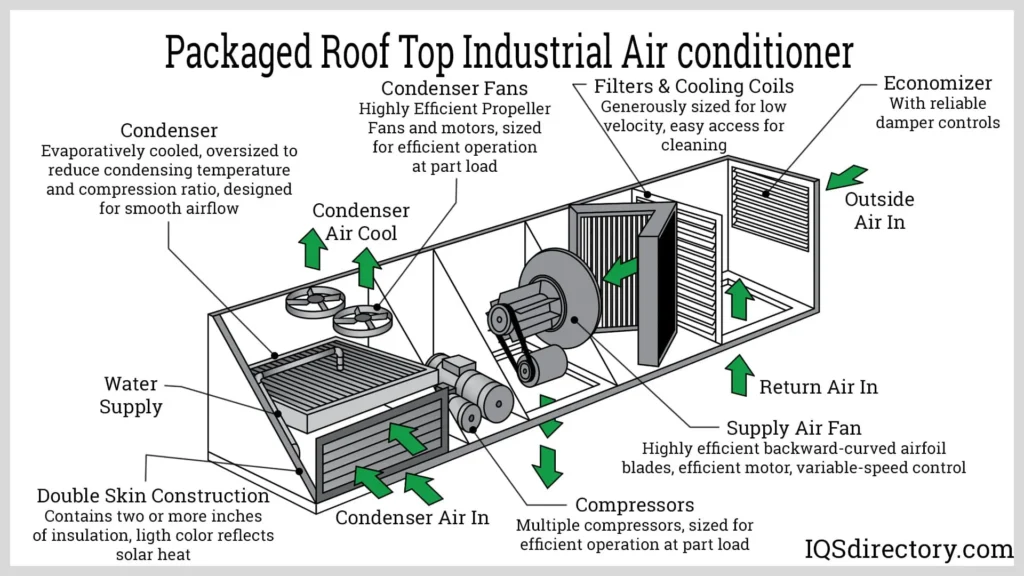

Power supplies, variable frequency drives, PLCs, and relays generate heat as a byproduct of normal operation. High-load components produce concentrated heat zones that can raise internal cabinet temperatures quickly. Without proper airflow, this heat accumulates and creates localised thermal stress.

As cabinet density increases, heat dissipation becomes more challenging. Identifying high-heat components is the first step in designing targeted and effective cooling.

External Environmental Heat Factors

Ambient temperature, nearby machinery, and solar exposure all influence cabinet thermal conditions. Outdoor installations or cabinets located near furnaces, compressors, or production lines are exposed to additional heat loads. Ignoring external factors often leads to under-designed cooling systems.

Typical Heat Load Sources Inside Industrial Cabinets

| Component Type | Heat Contribution | Cooling Priority |

|---|---|---|

| Power Supplies | High | Critical |

| VFDs & Drives | Very High | Critical |

| PLCs & Controllers | Medium | Moderate |

| Relays & Contactors | Low–Medium | Basic |

| Network Devices | Medium | Moderate |

This breakdown helps engineers focus cooling efforts where they matter most, instead of applying uniform airflow that fails to protect high-risk components.

Evaluating Cooling Needs Based on Cabinet Environment

High-Dust and High-Humidity Industrial Settings

Dust and moisture restrict airflow and damage internal components if not managed correctly. In such environments, cooling solutions must balance heat removal with contamination control. Improper ventilation can introduce dust that clogs filters and reduces cooling efficiency over time.

Indoor vs Outdoor Cabinet Conditions

Indoor cabinets usually experience more stable temperatures, while outdoor cabinets face wide temperature swings. Outdoor installations require cooling solutions that account for heat gain, weather exposure, and enclosure sealing requirements.

Selecting the Right Cooling Method for Industrial Applications

When Cooling Fans Are the Best Solution

Cooling fans are ideal for applications where ambient temperatures are within acceptable limits and contamination can be controlled. They are cost-effective, energy-efficient, and simple to maintain. For many industrial cabinets, fan-based cooling provides sufficient thermal control when designed correctly.

Fan Cooling vs Air Conditioners in Control Cabinets

Air conditioners are necessary when ambient temperatures exceed safe operating limits or when strict temperature control is required. However, they consume more energy and increase system complexity. Fan cooling is often preferred where possible due to lower operating cost and simpler maintenance.

Cooling Method Comparison for Industrial Control Cabinets

| Cooling Method | Best Use Case | Advantages | Limitations |

|---|---|---|---|

| Standard Fan Cooling | Moderate heat, clean areas | Low cost, simple design | Depends on ambient temp |

| Filter Fan (Positive Pressure) | Dusty environments | Prevents contamination | Filter maintenance needed |

| Cabinet Air Conditioner | High ambient heat | Precise temperature control | Higher energy use |

| Heat Exchanger | Sealed harsh environments | No air exchange | Limited cooling range |

This table prevents over-engineering and helps select the most practical cooling method based on real operating conditions.

Optimising Airflow Design Inside Industrial Cabinets

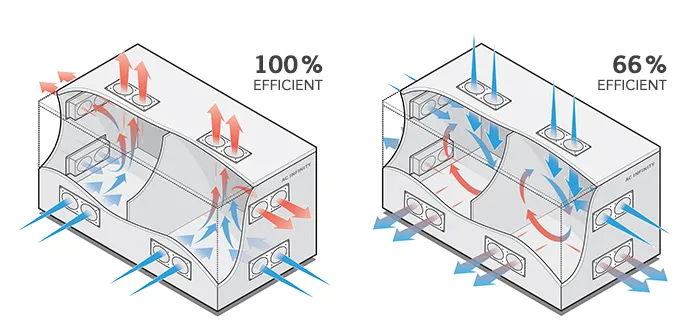

Positive Pressure vs Negative Pressure Airflow

Positive pressure systems push filtered air into the cabinet, preventing dust ingress through gaps. Negative pressure systems pull air out, which can draw contaminants inside if not sealed properly. In dusty environments, positive pressure is generally more effective.

Preventing Hot Spots Through Strategic Air Circulation

Uniform airflow prevents heat pockets around sensitive components. Poor circulation often results in hot spots that damage specific devices even when average cabinet temperature appears acceptable. Strategic airflow design ensures even heat distribution and removal.

Fan Placement Principles That Improve Cooling Efficiency

Intake and Exhaust Positioning Best Practices

Cool air should enter low in the cabinet and exit at the top, following natural convection. Proper spacing between intake and exhaust prevents short-circuit airflow, where air exits before cooling internal components.

Avoiding Common Installation Mistakes

Placing fans too close to heat sources, blocking airflow paths, or using undersized fans reduces effectiveness. Installation errors are a leading cause of cooling system underperformance.

Energy-Efficient Fan Control and Automation

Temperature-Based Fan Speed Regulation

Using temperature sensors to regulate fan speed reduces energy consumption and noise. Fans operate only when needed and adjust output based on actual thermal load, improving efficiency and component life.

Reducing Energy Consumption Without Compromising Cooling

Smart control strategies eliminate continuous full-speed operation. This approach lowers power usage while maintaining safe temperature limits, especially in cabinets with variable load conditions.

Custom Cooling Configurations for Complex Cabinet Designs

Multi-Fan Layouts for High-Density Equipment

High-density cabinets often require multiple fans to manage uneven heat distribution. Multi-fan layouts provide redundancy and more precise airflow control across different zones.

Modular Cooling Solutions for Scalable Systems

Modular cooling allows systems to expand without complete redesign. As equipment is added, cooling capacity can scale accordingly, protecting future upgrades.

Maintenance Planning to Ensure Long-Term Cooling Performance

Filter Cleaning and Dust Management

Clogged filters restrict airflow and reduce cooling efficiency. Regular inspection and cleaning schedules are essential to maintain designed performance levels.

Monitoring Fan Health and Failure Indicators

Fans are mechanical components subject to wear. Monitoring vibration, noise, and speed helps detect early failure signs and prevents sudden cooling loss.

Compliance, Safety, and Industry Standards in Cabinet Cooling

IP Ratings and Environmental Protection Requirements

Cooling solutions must maintain enclosure protection levels. Improper fan selection can compromise IP ratings and expose components to dust or moisture.

Meeting Industrial Electrical and Safety Standards

All cooling components must comply with relevant electrical, safety, and industrial standards to ensure safe operation, proper enclosure protection, and regulatory compliance in industrial environments.

Operational and Business Benefits of Proper Cabinet Cooling

Reducing Equipment Downtime and Failure Risks

Stable thermal conditions significantly reduce unexpected shutdowns and component failures. Reliable cooling directly supports production continuity.

Extending Component Lifespan and Improving ROI

Lower operating temperatures slow component degradation. Over time, this extends equipment life and improves return on investment by reducing replacement and repair costs.

Frequently Asked Questions About Industrial Control Cabinet Cooling

Why is cabinet cooling critical in industrial environments?

Excess heat accelerates component failure, causes downtime, and reduces system reliability, making cooling essential for stable operations.

Are cooling fans enough for all control cabinets?

No, fans work only when ambient temperatures are within limits; extreme heat or sealed cabinets require active cooling solutions.

What is the advantage of positive pressure cooling?

Positive pressure prevents dust and contaminants from entering the cabinet, protecting sensitive components in harsh environments.

How often should cabinet cooling systems be maintained?

Filters and fans should be inspected regularly, typically every few months, depending on dust levels and operating conditions.

Does proper cooling really improve ROI?

Yes, effective cooling extends component lifespan, reduces failures, and lowers maintenance and replacement costs over time.

Final Thoughts on Designing Reliable Cooling for Industrial Cabinets

Smart cooling strategies go beyond selecting fans or air conditioners. They involve understanding heat sources, environmental conditions, airflow dynamics, and long-term operational goals. When cooling is designed as an integrated system rather than an afterthought, industrial control cabinets become more reliable, efficient, and future-ready supporting both technical performance and business objectives. A well-planned industrial control cabinet cooling strategy turns thermal management into a long-term reliability and performance advantage.