Facility design plays a critical role in shaping how efficiently a business operates. It is not simply about fitting departments into available square footage; it is about aligning physical space with operational strategy. A well-designed facility supports productivity, reduces cost leakage, improves safety, and enhances both employee and customer experience. Conversely, poor layout decisions create friction, inefficiency, and hidden operational losses that grow over time. Strategic facility design turns physical space into a performance asset rather than a constraint for modern business operations.

Why Facility Design Directly Impacts Operational Efficiency

Facility layout determines how people, materials, and information move through an organisation. When these movements are inefficient, even well-designed processes fail to deliver results.

Productivity is directly influenced by layout quality. Employees lose significant time through unnecessary walking, searching, waiting, and task interruptions when layouts are poorly planned. Smart layouts minimise wasted motion, shorten task cycles, and allow teams to focus on value-generating work rather than navigating obstacles.

Cost control is another major outcome of good facility design. Inefficient layouts increase labour hours, material handling costs, energy usage, and space waste. Strategic layouts reduce these hidden expenses by improving proximity between related activities and optimising space utilisation.

Workflow stability depends on physical predictability. When layout follows process logic, operations become more consistent, easier to supervise, and less vulnerable to disruption. Stable workflows also improve planning accuracy and performance measurement.

Translating Business Objectives Into Functional Layout Decisions

Linking Space Planning to Core Operations

Effective facility design begins with a clear understanding of core business operations. Layout decisions should reflect how value is created, not simply architectural preferences. When space planning is aligned with operational priorities, processes flow naturally and performance improves without additional resources.

Designing for Present Needs and Future Growth

Facilities designed only for current demand quickly become bottlenecks. Strategic layouts account for future growth, process changes, and technology upgrades. Flexible zoning, modular layouts, and expansion-ready infrastructure protect businesses from costly redesigns and operational disruption.

Zoning Strategies That Reduce Bottlenecks and Task Overlap

Activity-Based Space Allocation

Different activities require different spatial conditions. Grouping related tasks together reduces travel time, communication delays, and task confusion. Activity-based zoning improves accountability and ensures each function operates in an environment designed for its specific requirements.

Separation of High-Traffic and Critical Zones

High-traffic areas introduce noise, distractions, and safety risks. Critical or precision-based activities should be isolated from these zones. Clear separation improves focus, accuracy, and safety while making supervision and process control more effective.

Optimising Movement Flow for Safety, Speed, and Accuracy

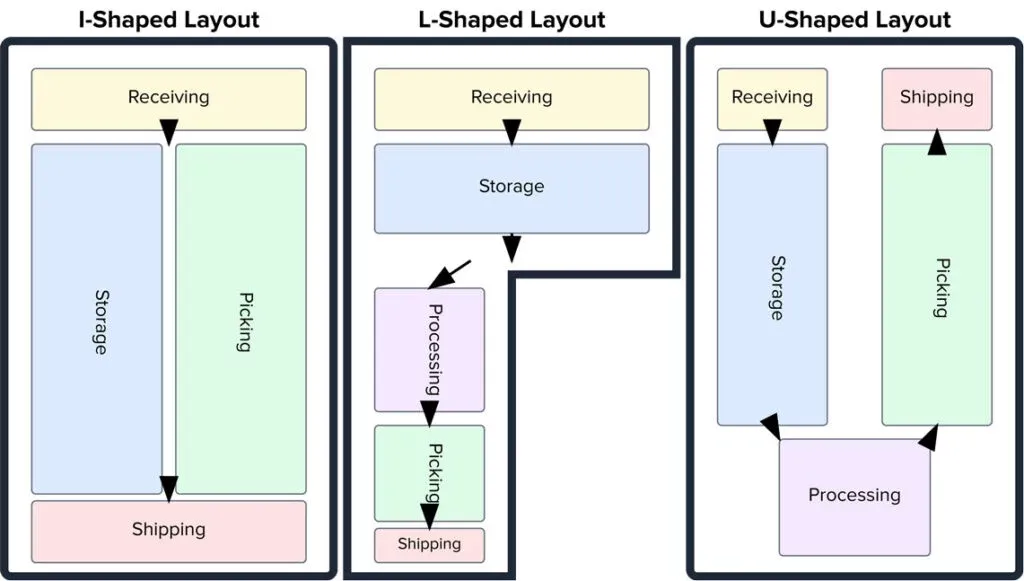

Reducing Cross-Traffic and Collision Risks

Unstructured movement paths increase accident risk and slow down operations. Strategic facility layouts define clear routes for people, equipment, and materials. This reduces congestion, lowers incident rates, and improves overall operational flow.

Designing Predictable Movement Patterns

Predictability reduces cognitive load and operational errors. When employees intuitively understand where to move and how processes flow, training time decreases and performance consistency improves. Predictable layouts support discipline and standardisation.

Designing Customer-Facing Areas That Support Trust and Conversion

First-Impression Design Principles

Customer-facing areas shape perception before any interaction occurs. Clean, logical, and intuitive layouts signal professionalism, reliability, and operational maturity. First impressions directly influence trust and purchasing decisions.

Functional Comfort Without Operational Disruption

Customer comfort must be delivered without interfering with backend operations. Strategic design balances accessibility and comfort while maintaining clear separation between customer spaces and operational workflows.

Employee-Centric Design for Productivity and Retention

Ergonomic Planning and Fatigue Reduction

Poor ergonomics lead to fatigue, injuries, and reduced productivity. Strategic layouts consider posture, reach zones, task repetition, and movement frequency. Ergonomic planning improves performance while reducing long-term health risks and absenteeism.

Supporting Focus, Accessibility, and Task Comfort

Employees perform best in environments designed around their tasks. Noise control, lighting, accessibility, and logical equipment placement improve focus and job satisfaction. Comfortable work environments also support retention and engagement.

Storage and Material Handling Design That Saves Time and Cost

Locating Storage Based on Usage Frequency

High-frequency items should be located closest to points of use. Poor storage placement increases travel time and handling effort. Strategic storage design directly improves speed, accuracy, and labour efficiency.

Minimising Retrieval Time and Handling Errors

Clear labelling, logical layout, and defined access paths reduce picking errors and rework. Efficient material handling lowers operational cost and improves service reliability.

Designing Facilities With Maintenance and Downtime Prevention in Mind

Access Planning for Equipment and Utilities

Maintenance efficiency depends heavily on access. Equipment that is difficult to reach causes longer shutdowns and higher service costs. Smart layouts ensure serviceability is built into the design from the start.

Reducing Operational Interruptions Through Smart Layouts

Separating maintenance access from active operational zones prevents unnecessary interruptions. This approach improves uptime, protects productivity, and extends equipment life.

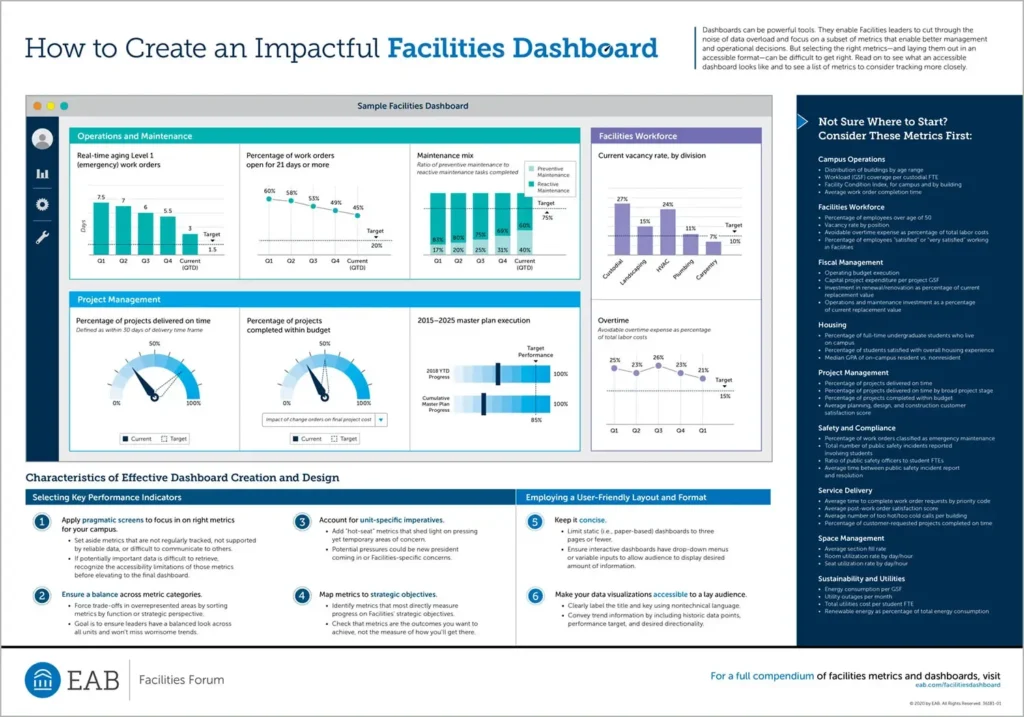

Using Data and Performance Metrics to Improve Facility Design Decisions

Modern facility design relies on data rather than assumptions. Space utilisation analysis identifies underused or overloaded areas. Workflow timing highlights bottlenecks and delays. Continuous optimisation ensures layouts evolve with operational demands.

| Metric | What It Measures | Business Impact |

|---|---|---|

| Space Utilisation | Actual vs planned usage | Reduced space waste |

| Travel Distance | Movement per task | Faster operations |

| Process Cycle Time | End-to-end workflow speed | Higher throughput |

| Error Rate | Layout-related mistakes | Quality improvement |

| Downtime Frequency | Layout-caused interruptions | Improved reliability |

Data-driven facility design transforms layouts into continuous improvement tools rather than static structures.

Common Facility Design Mistakes That Hurt Business Operations

Over-design introduces complexity without adding value. Ignoring process flow leads to congestion and inefficiency. Poor scalability planning forces expensive redesigns during growth phases. These mistakes typically occur when design decisions are made without operational input or performance data.

Frequently Asked Questions About Strategic Facility Design

What is strategic facility design?

Strategic facility design focuses on planning physical spaces around business operations, workflows, and long-term goals to improve efficiency and performance.

How does facility layout affect business productivity?

A well-planned layout reduces unnecessary movement, interruptions, and delays, allowing employees to complete tasks faster and with fewer errors.

Can facility design really reduce operational costs?

Yes, efficient layouts lower labour time, material handling costs, energy usage, and space waste, which directly reduces operating expenses.

Why is scalability important in facility design?

Scalable layouts allow businesses to grow or change processes without costly redesigns or operational disruption in the future.

How does facility design impact employee safety and retention?

Proper layouts improve movement flow, ergonomics, and safety, reducing injuries and fatigue while supporting long-term employee satisfaction.

Is facility design relevant for service-based businesses?

Yes, offices, healthcare, retail, and service facilities benefit from better layouts that improve customer experience and staff efficiency.

How often should facility layouts be reviewed?

Layouts should be reviewed whenever operations change or performance issues appear, and periodically to support continuous improvement.

What is the most common facility design mistake?

Designing based on space availability instead of actual process flow often leads to congestion, inefficiency, and higher costs.

Is strategic facility design a one-time project?

No, it is an ongoing process that should evolve as business needs, volumes, and technologies change.

Final Perspective: Facility Design as a Long-Term Business Asset

Strategic facility design is not a construction expense; it is a long-term operational investment. When layouts support people, processes, and future growth, facilities become enablers of performance rather than limitations. Businesses that treat facility design as a strategic asset achieve higher efficiency, lower costs, and greater resilience in competitive environments.